NanoMicrobiol NanoBiotechnol, 2022 (2), 202225

DOI:

Short Review

Design of experiments (DOE) and response surface analysis (RSA) in plant mediated synthesis of iron based nanoparticles

Narjes Ganjee 1

1 Department of Biotechnology, Institute of Environmental Sciences, Graduate University of Advanced Technology, Kerman, Iran

* Correspondence: nargesganjee@kgut.ac.ir

Abstract

Fabrication of metal nanoparticles can be performed by top-down or bottom-up approaches. Due to technical difficulties with top-down approach the fabrication process was majorly developed based on bottom-up approaches. In bottom-up approaches the metal ions such as iron ions are reduced to metal nanoparticles by using a reducing agent. Stabilizing agents were also employed in these reactions to control the growth and formation of nanoparticles. Reduction of metal ions to metal nanoparticles are usually performed by using a chemical reducer in an organic solvent. Due to environmental hazards of chemicals and organic solvents there are some efforts to make the process sustainable. Plant mediated synthesis is a green approach for the fabrication of metal nanoparticles that perform without employing any chemical or organic solvent. Like all other chemical reactions, plant mediated synthesis of metal nanoparticles needs to be optimized in terms of reaction condition to reach highest productivity. This can be achieved through the design of experiments (DOE) and response surface analysis (RSA).

Keywords: Iron based nanoparticles; Metal nanoparticles; Green synthesis; Plant mediated synthesis; Reaction optimization

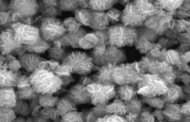

In recent years, the synthesis of metal nanoparticles has been highly considered due to various properties and applications in different fields. Among these nanoparticles, iron nanoparticles have attracted a lot of attention due to their unique magnetic, catalytic, electronic, and thermal properties. Iron nanoparticles contain different types, each of which has special properties that cause their different applications in industry, medicine, and environment (1, 2).

So far, extensive studies have been conducted to synthesize iron nanoparticles using chemical and physical methods. In general, physical and chemical methods of producing iron nanoparticles are carried out with two major top-down or bottom-up approaches. The top-down approach includes reducing the size of bulk iron particles to reach the nanoscale, which is done through chemical and mechanical processes such as grinding, etching, vacuum sputtering, or degradation of pentacarbonyl iron (Fe(CO)5) in organic solvents (3, 4). Bottom-up approach involves the use of iron ions and the creation of nanostructures through chemical processes. The most common method of this approach is the reaction of ferrous or ferric ions with chemical reducers (5).

Each of these chemical and physical methods has faced certain problems and limitations in the synthesis and production processes. For example, top-down methods require special, sophisticated, and expensive equipment that makes production costly and energy-intensive. Therefore, they are not economically affordable. Although at first glance, bottom-up approach seem to be a very simple, fast that can be performed without special equipment, but this method rises major concerns in terms of safety and environmental risks. In this method, toxic chemicals are used as reducing and stabilizing agents for the synthesis of iron nanoparticles that rises environmental concerns. Also, there are some safety issues, for instance, some chemical reducing agents such as sodium borohydride or hydrazine can produce flammable hydrogen gas. Therefore, special measures are needed to protect operators and remove toxic substances which produced in the production process (3, 5-7).

In recent years, researchers have been looking for a simple, inexpensive, and safe method that can be performed without the need for sophisticated equipment. The use of biological systems including plants and microorganisms as well as natural and biocompatible materials such as vitamins and polymers for the production of metal nanoparticles is a good opportunity to achieve this goal. These materials are used as natural reducing and stabilizing agents that lead to the manufacture of iron nanoparticles with considerable properties (1, 8). Green synthesis of iron nanoparticles is a healthy, safe and cost-effective alternative method compared to common physical and chemical methods. One of the green synthesis methods of nanoparticles is plant-mediated synthesis, which is used by plant extracts to synthesize nanoparticles (8). The synthesis of iron nanoparticles by plants has become a turning point in the production and application of iron nanoparticles. In this method, the synthesis of iron nanoparticles is done simply by mixing iron ion precursor with plant extract without the use of additional reducing or stabilizing agents. The reaction can be conducted under mild condition and temperate, such as ambient condition (1, 8).

Plant extracts contain many antioxidant substances including polyphenols, flavonoids, cofactors, regenerative sugars, proteins, nitrogenous bases and amino acids that can act as reducing and stabilizing agents for the fabrication of iron nanoparticles (8). But the reaction is not so simple, various parameters can affect the synthesis reaction such as reaction temperature, reaction time, concentration of iron precursor, and amount of plant extract (9).

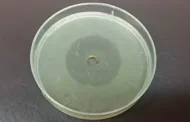

It is obvious that the first step toward achieving the best result is to find the factors involved in the green synthesis process of these nanoparticles. The second step is to find and setup the optimal synthesis condition. Studies conducted by researchers in this regard have been mostly aimed at investigating the synthesis conditions by one factor at a time, so that at one time and one reaction only one factor is investigated and other factors are constant (9). In such experiments, the interactions and effects of different factors on each other are not investigated. Therefore, in recent years by using a design of experiment software more advanced studies were conducted to examine the impacts of reaction parameters in combination. In this regard, at first it is tried to identify the factors affecting the biosynthesis process of nanoparticles. In the second stage, it is tried to identify the effect of different factors in interfering form. Finally, it is tried to identify the optimum state for each of the factors affecting the synthesis of nanoparticles and obtain optimal conditions for synthesis (10, 11). For instance, in an experiment that was conducted by Keshtzar et al. design of experiments (DoE) and response surface methodology (RSM) was employed to discover important parameters and optimal reaction condition in the green tea mediated synthesis of zero valent iron nanoparticles. They found that amount of plant extract and iron precursor concentration are the most effective parameters (10). Similar study was also conducted by using pine tree needles extract for the green synthesis of zero valent iron nanoparticles (11). These findings indicate the importance of reaction condition and reaction optimization for the green synthesis of metal nanoparticles.

Conclusion

Plant mediated synthesis of metal nanoparticles is a simple reduction reaction but need immense knowledge about the optimal reaction condition to reach the best result. Various reaction parameters such as reaction temperature, reaction time, concentration of metal precursor, amount of plant extract, and reaction pH can affect the resulted particles. The best reaction condition can be achieved by design of experiment and response surface analysis.

References

-

- Markova Z, Novak P, Kaslik J, Plachtova P, Brazdova M, Jancula D, et al. Iron (II, III)–polyphenol complex nanoparticles derived from green tea with remarkable ecotoxicological impact. ACS Sustainable Chem Eng. 2014;2(7):1674-80.

- Xiao Z, Yuan M, Yang B, Liu Z, Huang J, Sun D. Plant-mediated synthesis of highly active iron nanoparticles for Cr (VI) removal: Investigation of the leading biomolecules. Chemosphere. 2016;150:357-64.

- Wang T, Jin X, Chen Z, Megharaj M, Naidu R. Green synthesis of Fe nanoparticles using eucalyptus leaf extracts for treatment of eutrophic wastewater. Sci Total Environ. 2014;466-467:210-3.

- Hola K, Markova Z, Zoppellaro G, Tucek J, Zboril R. Tailored functionalization of iron oxide nanoparticles for MRI, drug delivery, magnetic separation and immobilization of biosubstances. Biotechnol Adv. 2015;33(6):1162-76.

- Machado S, Pinto S, Grosso J, Nouws H, Albergaria JT, Delerue-Matos C. Green production of zero-valent iron nanoparticles using tree leaf extracts. Sci Total Environ. 2013;445:1-8.

- Wang Z, Fang C, Mallavarapu M. Characterization of iron–polyphenol complex nanoparticles synthesized by Sage (Salvia officinalis) leaves. Environ Technol Innov. 2015;4:92-7.

- Machado S, Stawiński W, Slonina P, Pinto A, Grosso J, Nouws H, et al. Application of green zero-valent iron nanoparticles to the remediation of soils contaminated with ibuprofen. Sci Total Environ. 2013;461:323-9.

- Makarov VV, Makarova SS, Love AJ, Sinitsyna OV, Dudnik AO, Yaminsky IV, et al. Biosynthesis of stable iron oxide nanoparticles in aqueous extracts of Hordeum vulgare and Rumex acetosa plants. Langmuir. 2014;30(20):5982-8.

- Taghizadeh S-M, Zare-Hoseinabadi A, Berenjian A, Ghasemi Y, Ebrahiminezhad AJJoETT. Effective Parameters in the Green Synthesis of Zero-valent Iron Nanoparticles as a Fenton-like Catalyst. Journal of environmental treatment techniques. 2020;8(1):442-7.

- Kheshtzar R, Berenjian A, Ganji N, Taghizadeh S-M, Maleki M, Taghizadeh S, et al. Response surface methodology and reaction optimization to product zero-valent iron nanoparticles for organic pollutant remediation. Biocat Agr Biotechnol. 2019:101329.

- Kheshtzar R, Berenjian A, Taghizadeh S-M, Ghasemi Y, Asad AG, Ebrahiminezhad A. Optimization of reaction parameters for the green synthesis of zero valent iron nanoparticles using pine tree needles. Green Proc Synth. 2019;8(1):846-55.